Laser welding offer flexible working methods, contactless welding limits mechanical and thermal stresses. It is easy to automate high-speed welding, and it can also be controlled by digital or computer.

When welding thin materials or thin-diameter wires, it is not as easy to be troublesome as arc welding. Two metals with different physical properties (such as different resistances) can be welded.

It is mainly used in the automotive industry, medical industry, etc., the products are mainly the welding of micro parts (such as precision electronic parts) and parts with poor accessibility, as well as the welding of some thin plates.

Laser welding has the following advantages over other welding way: high cleanliness, non-dust, non-particles; directional local linear heating, so it has no influence on the surroundings; Non-vibration welding; for the complex structure products, the track can be programmed in 2D or 3D.

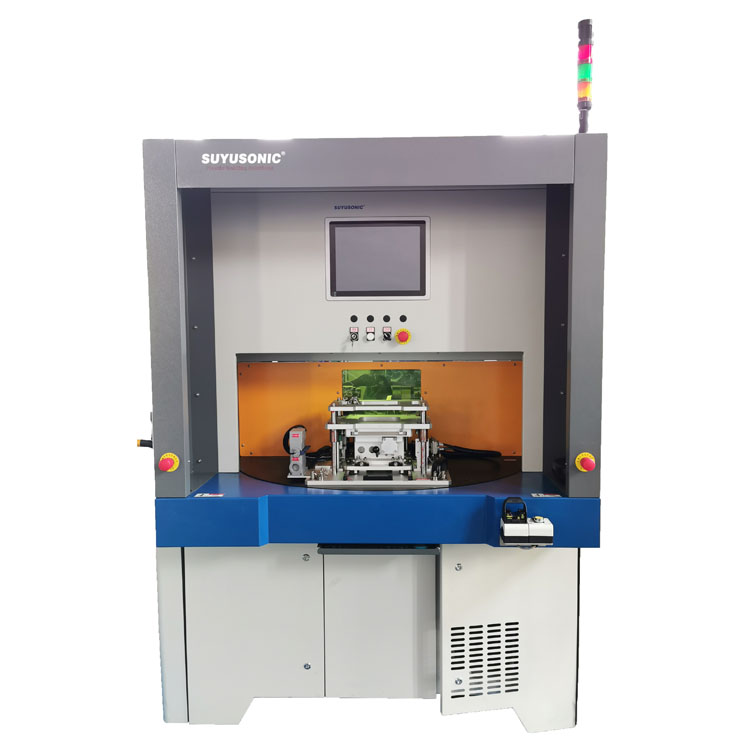

Our main representative products are 360 circular tube plastic laser welding machine, 380V 25A Energy saving Laser plastic welding machine, laser marking equipment for Automobile industry, etc.